Plastic injection and shredding machines

This project was put on hold due to the large nature of the project so is only partially finished.

I wanted to make these machines so I could recycle plastic and make products from these materials in house instead of throwing them away into a landfill or for incineration. The base of these designs are from open source designs created by Precious Plastic.

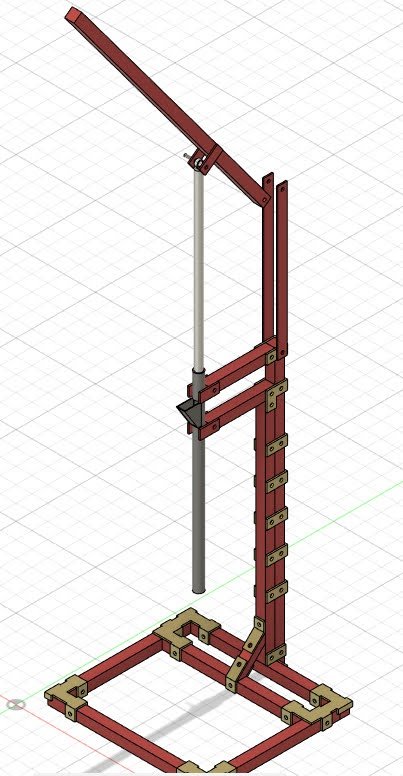

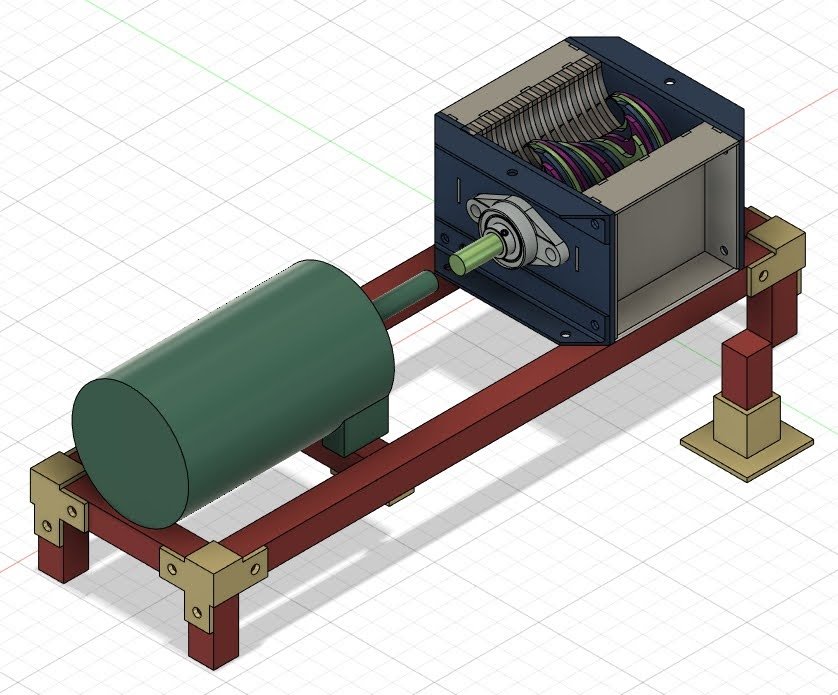

With this project my main goal was to modify the base designs so that they would be compact during transport and thus needed to be able to be disassembled. To do this I needed to 3D model the design so used my, at the time, 6 months experience using Fusion360 and 3D printing to create the models that can be seen below.

Once these machines were fully built, I tested out the shredder and found that it did shred plastic, but my motor wasn’t powerful enough to handle thick plastic, and that my 3D printed brackets at the corners were not strong enough for this application. To solve this issue I fabricated some metal brackets to replace the printed ones which solved that issue and allowed me to shred more plastic. I unfortunately didn’t have the money to be able to upgrade the motor so I stayed with what I had at the time.

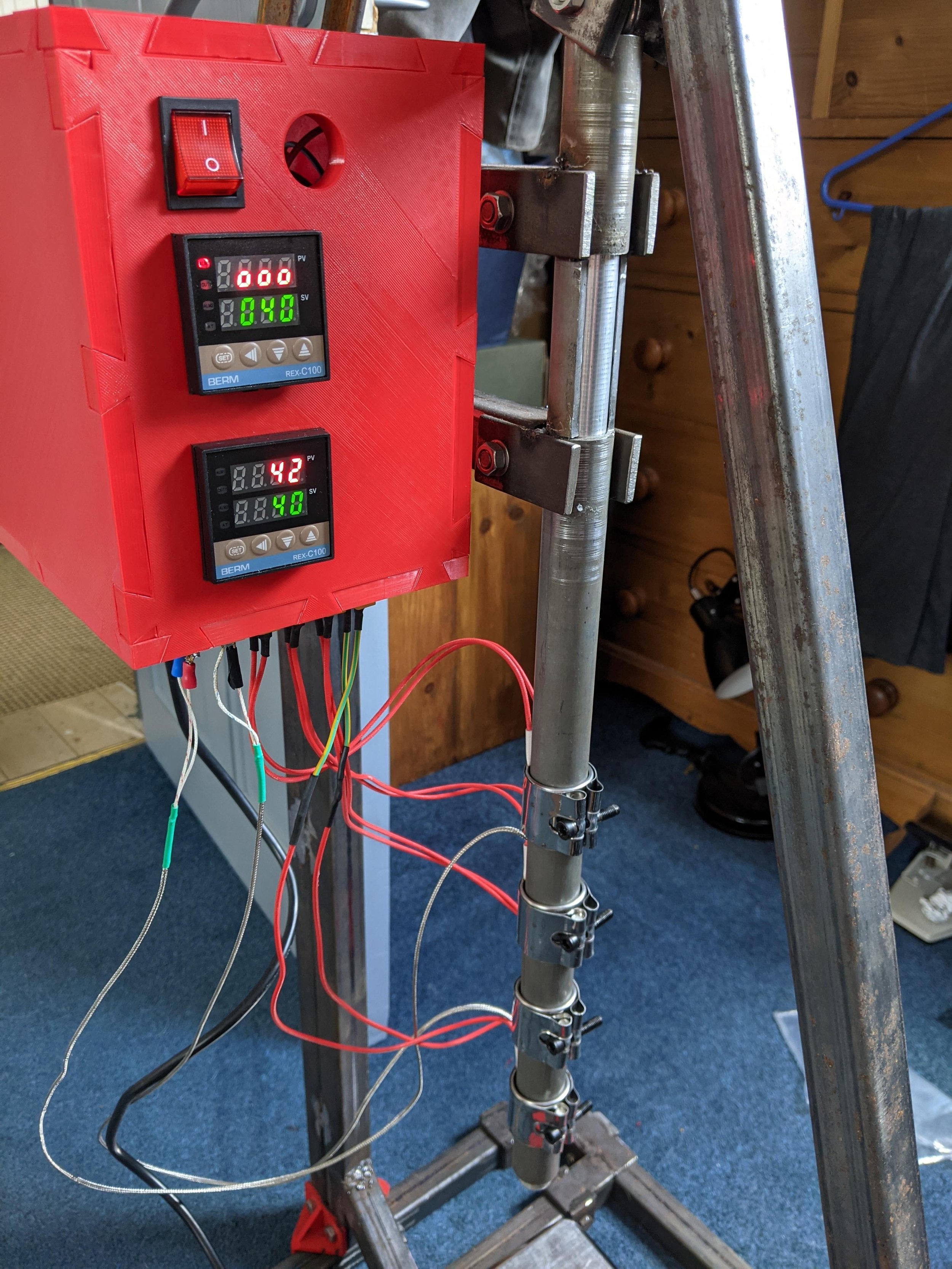

I also built up the entire injection moulding machine and managed to heat the injection chamber and maintain that temperature, but this machine suffered the same fault that the shredder did with its plastic brackets to metal ones were also needed for this machine to resolve that issue. The machine also needed some way of attaching moulds to the output so I also had to figure out that challenge but it took a long time to design due to my inexperience in the area.

Unfortunately this is where this project got shelved as my second year of University started and I haven’t been able to continue this project since.